Our Company

The Daniel Weaver Company

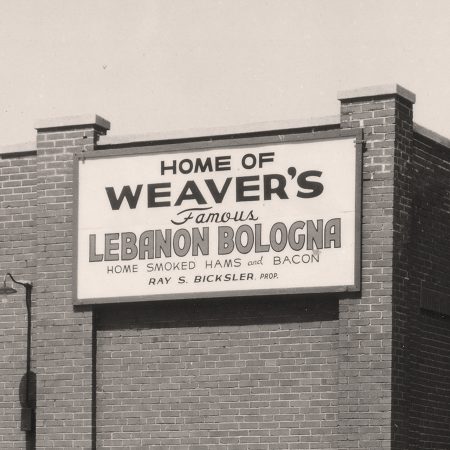

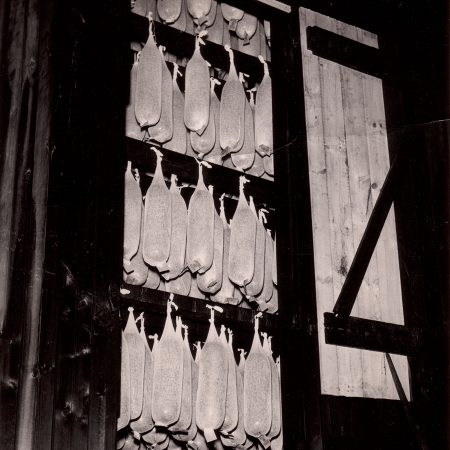

Founded in 1885 the Daniel Weaver Company has been crafting meat snacks at the same location in Lebanon, Pennsylvania for over 135 years. In the late 1800’s, Daniel Weaver dreamed of creating a smoked beef snack that would keep without refrigeration. His persistence and commitment to quality led to a successful process and we have been making quality smoked snacks ever since. The way we produce our snacks hasn’t changed much over the past century.

Godshall's Quality Meats

Since 1945, Godshall’s has been dedicated to supplying premium meat specialty items to family tables everywhere. From a local family butcher shop to an international supplier, we pride ourselves on our quality, freshness and taste. And it all starts on the farm–the land and the animals. The welfare of both is a responsibility we take to heart because we care about the world we live in.

Testimonials

Godshall's History of Quality

1940s

The Godshall family at their home, which is now used as administrative offices.

1945

The company is founded by Marvin K. Godshall in a meat production plant behind his own home in Telford, Pennsylvania. The original building continues to be used today.

1960s

Godshall’s butcher shops begin expanding across Pennsylvania, showcasing an array of delicious homemade premium meats.

1970s

Godshall’s hits the road and expands to farmer’s markets and butcher shops across Pennsylvania.

1980s

The company continues to thrive and expands its meat processing plant behind the family home. The phrase “homemade” is taken to the next level.

1985

We had 7 butcher shops across Pennsylvania. These were eventually phased out when the company began to focus on manufacturing, supplying customers nationwide.

1990s

In their 3rd generation of family leadership. Mark Godshall (Chairman) and Ron Godshall (current President) hand make delicious sausages.

2001

Godshall’s purchases the Kutztown Bologna Company, which diversifies our premium smoked meat portfolio.

2005

Godshall’s acquires the Daniel Weaver Co. in Lebanon PA, which was founded in 1885. Through continued investment it is now our largest plant.

2016

The company opens a dedicated Distribution Center and a state of the art R&D and Culinary facility in Souderton, PA.

2017

We make history by becoming an Employee-Owned Company (ESOP), where all team members share in the success of the organization.

2021

Godshall’s breaks ground on a new plant expansion in Lebanon, PA. The project was completed in 2023 and the facility now covers more than 150,000 ft2.

2023

Godshall’s purchases a processing plant in Emmaus, PA from Clemens Food Group. The facility will allow the company to further diversify its portfolio and production capabilities.

2023

Godshall’s make history and sets the Guinness World Record for the Longest Piece of Turkey Bacon measuring 17 ft ¾ in and 1.92 ft wide. The record setting slice was over 1500 times larger than a regular piece of turkey bacon!

Our Quality Serves Your Customers

Godshall’s is comprised of some of the best PhDs, food scientists, chefs, product managers and data-driven marketers in the business with a customer service focus that gets results. From some of the world’s biggest food brands, national restaurant chains to start-up companies and leading universities, we’ve worked successfully with them to produce delightful category leading food.

What’s cookin’? Our R&D and Culinary Team are consistently working with on-trend concepts and new applications at our remarkable Innovation Center, which was completed in 2017. Our Innovation Center is USDA Certified and features a complete pilot plant equipped with Injectors, Grinders, Stuffers, Tumblers, Emulsifiers, Packaging Machines and Smokehouses – all in an effort to innovate what’s next in delicious.

To ensure wholesomeness and food safety, our on-site lab facilities are a hub of activity where we conduct microbiology, sensory and shelf life testing. The fully outfitted commercial and residential kitchen mimic meal preparation for both home and foodservice ensuring our customers consistently receive the best food possible.

Innovation Center

- We are able to make recipe adjustments quickly as sensory feedback is received.

- Real-time microbiology and product quality testing capabilities.

- Ability to quickly go from paper concepts to complete-small scale production

- Shelf-life and packaging testing

Our Products